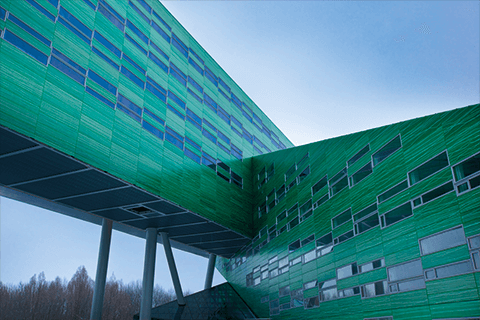

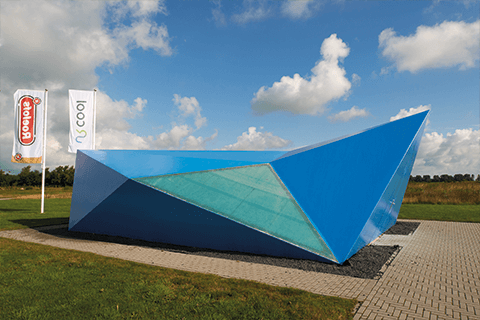

Design

freedom

Fire

retarding

Low

maintenance

Long

lifespan

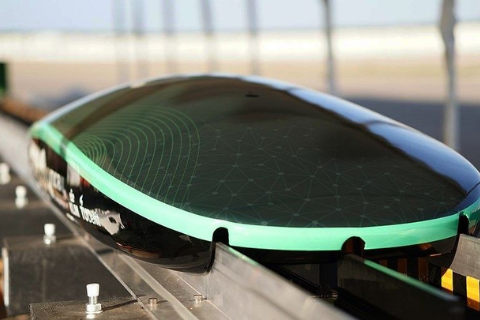

Precision milling carbon chassis for Delft Hyperloop

For Delft Hyperloop Holland Composites has carried out precision milling work with a total of 60 different sized holes in a carbon chassis. The part is part of the Hyperloop competition of SpaceX, a competition between student teams from technical universities all over the world.

Our extensive machine park includes a 5-axis CMS-Ares CNC milling machine with a working range of 5.5 x 2.5 x 2 metres. It is specially equipped for precision milling work in carbon, wood and light aluminium. Do you also have a challenge in the field of precision milling for your carbon composite products? We like to take it on!

Composite in the medical industryx

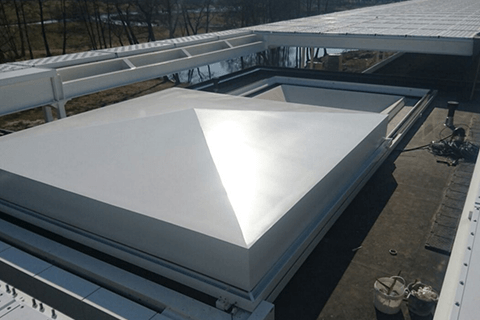

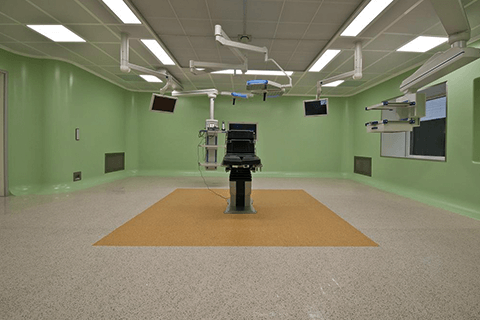

Modular composite cleanroom

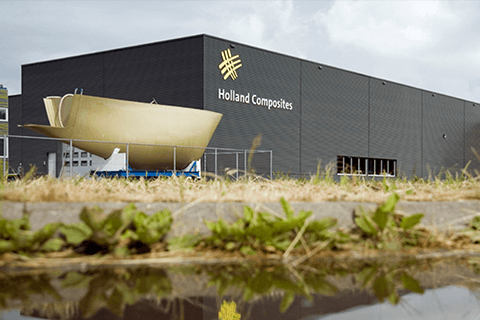

As a composite manufacturer we are often approached for the most diverse projects & assignments, and that excites us. Our engineering team likes a challenge, and we like to be creative with composites. Here are some examples of our special products:

Holland Composites has developed a modular system for walls of Operation room / clean rooms for the client. It is a complete operating room that meets all regulations and strict requirements.

This modular cleanroom is a solution for refurbishment, relocation or a temporary capacity problem where the OR / Operation Room / Cleanroom can be installed externally - as a new construction against an outer wall or indoors in an existing room / building. By using an innovative composite construction, the number of seams and sharp corners in the OK reduced to a minimum, making the room easy to clean. This ensures optimum hygiene and saves considerably on the cleaning costs.

Composite in the automotive industryx

Audi Windtunnel Composite Sensorarm

We have produced the composite sensor arm for the Audi Wind tunnel. Customer requirements were clear: a light and strong sensor arm that does not vibrate when it is kept next to an Audi sports car running at 250 km/h in the "Ingolstadt" wind tunnel. In addition, the sensor arm also had to be as thin as possible, so that it caused as little turbulence as possible in the wind tunnel. We created this sensor arm on behalf of Solico Engineering. This was not an easy task. But with the right designs, calculations and materials, Solico Engineering and amongst others Holland Composites have been able to deliver this according the expectations of the customer. A good example of yet, another perfect special project collaboration.