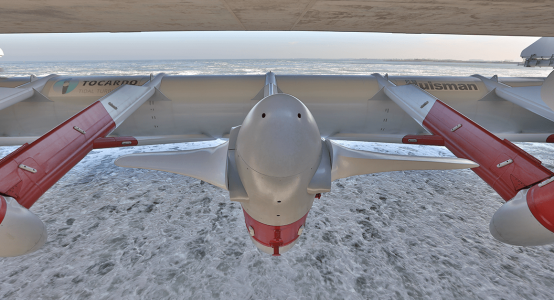

Composite tidal blades Tocardo

Project detailsx

Client: Tocardo Tidal Power

Location: Den Oever, Netherlands

Year: 2012

Surface: m2

Material: Composite

Specifics: Extremely strong and efficient tidal blades made of composite. Not all composite companies can develop and make this. Everything revolves around efficiency, so the shape and design of the blades are crucial to the success of our turbines blades that have to perform day after day with minimal maintenance.

We make the composite tidal turbine blades for Tocardo Tidal Power. It is the largest project for tidal energy in the Netherlands and the largest commercial tidal installation in the world. It’s also the first time a series of five turbines were installed side by side.

For almost sixty years, the Delta Works have protected a large part of the Netherlands against flooding from the sea. Now the Oosterscheldekering also has the function to generate energy. The flood defense is the most suitable location for generating tidal energy in the Netherlands because of the strong currents. At the fixed rhythm of the ebb and floods the turbines of Tocardo generate safe and predictable electricity. The turbines have been operating smoothly for years and have a total capacity of 1.2 MW, good for the power supply of 1000 households.

The turbine blades in tidal turbines at the Oosterscheldekering have been running successfully for years now. They provide about one thousand Zeeland households with clean electricity every day of the year.

At fierst glance it may look simple: beautiful white shaped parts that seem to be molded. However, the composite turbine blades are a technical masterpiece. The turbine blades must be maintenance-free for a long time (they are placed under water and therefore difficult to access) and the maximum forces on the turbine blades were immense. So these blades really have to be very strong.

Let’s clarify the term ‘very strong’ a bit more: a set of turbine blades (two blades) provides as much force as a sea tug boat under maximum load / at full power.

Holland Composites produced these composite tidal turbine blades after having developed them together with engineering firm Solico. These turbine blades have to meet particularly high requirements in terms of both strength and durability, resulting in a particularly thick-walled composite structure.