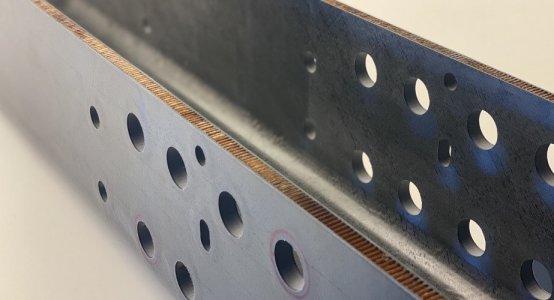

Precision Milling Carbon Chassis Delft Hyperloop

Project detailsx

Client: Delft Hyperloop

Location: Delft, the Nederlands

Year: 2020

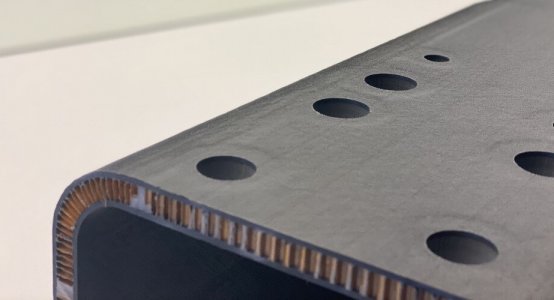

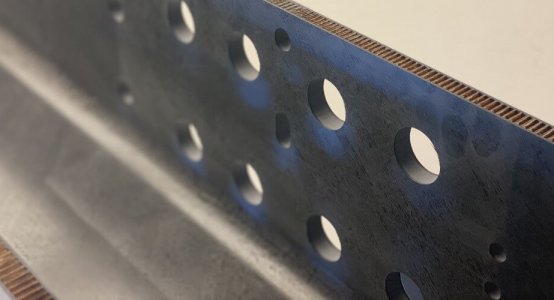

Material: Composite and Nomex pre-preg

Specifics: For Delft Hyperloop Holland Composites has carried out precision milling work with a total of 60 different sized holes in a carbon chassis. The element is part of the Hyperloop competition of SpaceX, a competition between student teams from technical universities all over the world.

Our extensive machine park includes a 5-axis CMS-Ares CNC milling machine with a working range of 5.5 x 2.5 x 2 metres. It is specially equipped for precision milling work in carbon, wood and light aluminium.

In collaboration with Delft Hyperloop, our milling machine experts have worked in a short period of time on the details of the design and the machining operations to be carried out. The numbers were converted into data for the milling machine, after that the precision milling of the carbon part was started.

After only a few hours the carbon chassis for Delft Hyperloop was ready. The 5-axis milling machine is fast and also provides an extremely refined finish, making manual finishing almost unnecessary. Because of this, Team Delft Hyperloop had the chassis back quickly, so they could continue their project at full speed.

Precision milling of the carbon chassis for Delft Hyperloop by Holland Composites. Do you also have a challenge in the field of precision milling work for your carbon composite products? We like to take it on!

Contact