Project detailsx

Client: Defence Customers

Location: Global

Year: 1999-present

Surface: 2700 m2

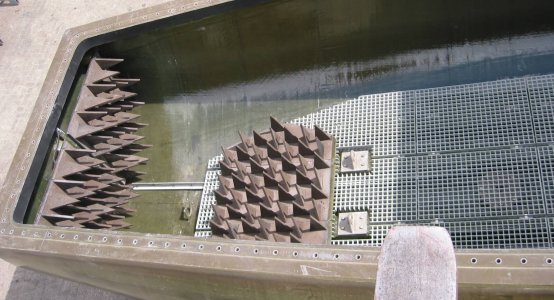

Material: Thick GRP or CFRP

Specifics: Since 1999 we have been able to produce sonar domes made in 1 piece with our new technique. Until then, sonar domes were either of metal or glued from multiple (composite) parts. Obviously ours are stronger!

One of our specialties: making large, complex shaped, thick-walled composite sonar domes in a single production run.

In 1999 Holland Composites developed a new technique to produce sonar domes – the protruding spherical part under the predestination of large (war) ships/ frigates, in which the sonar is housed. Until that time, sonar domes were either made of metal, or glued from several (composite) parts.

To search under water, sonar technology is used. There are two types: active sonar and passive sonar. An active sonar emits a sound: if the sound collides with an object, it bounces back. With this data you can determine that something is present and about where. A passive sonar emits nothing, but only listens to ships or submarines making noise.

Warships like frigates usually use active sonars, because they make too much noise themselves (hull, machinery and propellers) to use the passive sonar properly. So the underwater world is a world of sound: the one who is quietest and/or can hear the farthest, wins.

We produce a single composite construction – without secondary connection – with a wall thickness of 20 to 80 mm, which protects the sonar system against blows and vibrations.

Well-known advantages of composite are strength and stiffness at a relatively low weight, as well as longer lifespan and minimal maintenance. Another major advantage is that the density of a composite laminate is closer to the density of water. As a result, the propagation speed of sound is less annoyed, which leads to better data. Further optimization is possible by producing a partially viscoelastic laminate.

With materials such as E-glass and a hybrid vinylester/epoxy resin, the vacuum injection process enables us to achieve a high fibre volume content of 70%. This results in a robust and cost-efficient product.

Other important properties are the absence of air inclusions (airvoids) in the laminate and the very uniform wall thickness. Due to the minimal disturbance, the reliability of the sonar data is increased.